Introduction to

Autoclaved Aerated Concrete (AAC) & Autoclaved Lightweight Concrete (ALC) Panel

Autoclaved Aerated Concrete (AAC) / Autoclaved Lightweight Concrete (ALC) is a lightweight cellular material, produced with cement, lime, silica sand as raw material. The cellular structure is achieved by either a chemical process causing aeration, or by introducing air voids by mechanical means into a slurry which contains no coarse material The aeration is caused by the addition of a small quantity of acidic aluminum paste that reacts with the alkaline lime &; cement to expand the mixture. A two-way welded steel reinforcement mesh is than processed with anti corrosion liquid and inserted into the mold. It is than sent for Autoclaving process for curing before being transported to be packed and shipped.

FortisLite Autoclaved Aerated Concrete (AAC)/ Autoclaved Lightweight Concrete (ALC) panel is processed according to the definitized size for ease of onsite construction. As prefabricated product with high precision, ease of cutting and drilling, it is one of the better choice of precast panel for construction, The simple installation method and lightweight of the Autoclaved Lightweight Concrete (ALC) panel greatly shorten construction time and increase the efficiency and quality of construction.

Autoclaved Aerated Concrete (AAC) Panel is suitable for load bearing and non load bearing applications. FortisLite Autocalved Aerated Concrete (AAC)/Autoclaved Lightweight Concrete (ALC) panel is suited for use in Internal wall & External Wall applications.

⇒ Residential Properties

⇒ Commercial Properties

⇒ Hospitals

⇒ Factories

⇒ Industrial Properties

⇒ Public Infrastructures

⇒ Hotels

⇒ College’s

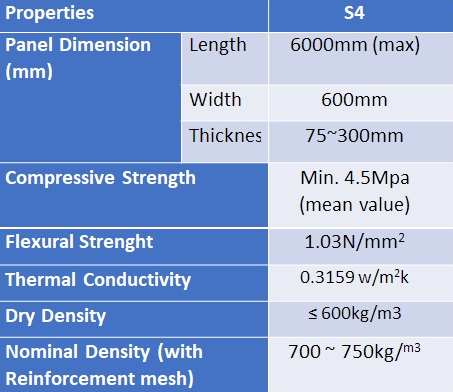

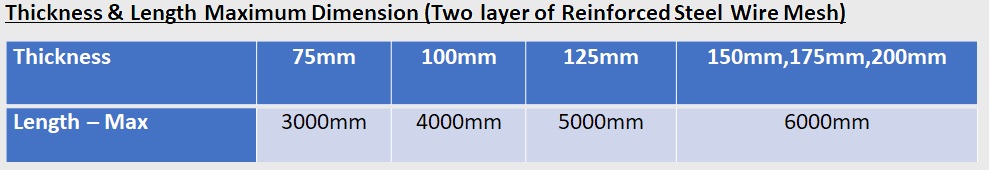

FortisLite ALC Panel (Standard) Data - Specifications

FortisLite Autoclaved Aerated Concrete (AAC)/Autoclaved Lightweight Concrete (ALC) Panels are manufactured to stringent ISO quality processes. The AAC/ALC panels are available in a multitude of sizes. FortisLite ALC wall panel system are installed using brackets and adhesive to structural areas such as Concrete/steel beams, columns as infill walls.

Autoclaved Aerated Concrete (AAC)/Autoclaved Lightweight Concrete (ALC) panels are commonly used in various type of properties ranging from commercial factories, industrial buildings, shopping malls, hospitals, schools etc.

Reports & Certification From

Benefits of Autoclaved Aerated Concrete (AAC) / Autoclaved Lightweight Concrete (ALC) Panel

Intrinsic Benefits

Eco-Friendly Product

FortisLite ALC Panel is manufactured from inorganic material, such that it is free from allergenic substance and toxic substance. The lower consumption of raw materials due to aeration during the manufacturing process also contribute to the environment. Furthermore, waste and materials from the manufacturing process can be recycled during the entire process.

FortisLite ALC Panel is manufactured from inorganic material, such that it is free from allergenic substance and toxic substance. The lower consumption of raw materials due to aeration during the manufacturing process also contribute to the environment. Furthermore, waste and materials from the manufacturing process can be recycled during the entire process.

Thermal Insulation

FortisLite ALC Panel has excellent thermal insulation quality, the inherit material makes it a superior choice as an insulation material due to its thermal resistances properties. It takes less energy to cool or heat up the material which make it a smarter choice to meet stringent eco building requirements.

FortisLite ALC Panel has excellent thermal insulation quality, the inherit material makes it a superior choice as an insulation material due to its thermal resistances properties. It takes less energy to cool or heat up the material which make it a smarter choice to meet stringent eco building requirements.

Acoustic Performance

The robustness & porous properties of FortisLite ALC Panel acts as sound insulation & absorption barrier that is able to deliver excellent performance in sound & acoustic insulation. FortisLite Panel is able to achieve superior sound transmission cancelation of up to 50 STC when finished with plastering & skim to deliver quieter building quality.

The robustness & porous properties of FortisLite ALC Panel acts as sound insulation & absorption barrier that is able to deliver excellent performance in sound & acoustic insulation. FortisLite Panel is able to achieve superior sound transmission cancelation of up to 50 STC when finished with plastering & skim to deliver quieter building quality.

Fire Insulation & Integrity

FortisLite ALC Panel is non-combustible and has excellent fire rating properties. It is 4 hours fire rated and is suitable for fire-rated applications. The porous property of the material also makes it heat up significantly longer and slower compared to other masonry materials.

FortisLite ALC Panel is non-combustible and has excellent fire rating properties. It is 4 hours fire rated and is suitable for fire-rated applications. The porous property of the material also makes it heat up significantly longer and slower compared to other masonry materials.

Lightweight

FortisLite ALC Panel net dry density is up to 3 times lighter than traditional concrete building materials. This in turn translate to easier handling and transportation during installation of the material. Furthermore, the lightweight of FortisLite Panel means there may be cost savings from the reduction in structural and foundational requirements for high-rise buildings.

FortisLite ALC Panel net dry density is up to 3 times lighter than traditional concrete building materials. This in turn translate to easier handling and transportation during installation of the material. Furthermore, the lightweight of FortisLite Panel means there may be cost savings from the reduction in structural and foundational requirements for high-rise buildings.

Durability

FortisLite ALC Panel is manufactured to the most stringent of ISO quality management system with German Technology. This process ensure that the panels has durability quite similar to concrete and is imbedded with corrosion coated steel-reinforced mesh for added degree of strength, durability and security.

FortisLite ALC Panel is manufactured to the most stringent of ISO quality management system with German Technology. This process ensure that the panels has durability quite similar to concrete and is imbedded with corrosion coated steel-reinforced mesh for added degree of strength, durability and security.

Extrinsic Benefits

Fast Construction

Fast Construction

FortisLite ALC Panels intrinsic lightweight means that the panels are easier to handle during construction. This means that less labour is required compared to traditional masonry construction methods for the same build up area leading to faster construction and cost savings.

Energy Saving & Consumption

Energy Saving & Consumption

The excellent thermal properties of AAC/ALC materials due to its porous nature by trapping large quantity of air in those pores so that the air is not able to circulate thus less thermal transmission. This results in significant cost savings from air conditioning requirements.

Environmental Friendly & Recyclable Production

Environmental Friendly & Recyclable Production

The manufacturing process of AAC uses significantly less raw material to produce the same amount of cubic meter of traditional masonry materials as approximately 80% of the material is aerated. Additionally, the waste during the production process can also be recycled back to the production process. This translate to better and greener environmental conservation.

Cost Savings

Cost Savings

The inherit lightweight properties of the AAC allows for faster installation, reduction of structural size requirements compared to other masonry materials. Additionally, AAC Panels allows for the length to be designed and customized to size requirement for column to column or floor to ceiling fitment. This translate to additional cost saving from stiffener and lintel requirements.

Environmental Sustainability

Eco-Friendly

FortisLite ALC panel is a eco-friendly material. It is manufactured with up to 20% of recycled materials and has achieve 4 ticks from the Singapore Green Building Council for its ecological benefits.

Production & Delivery

FortisLite ALC panel are produce to stringent ISO production standards. This standards accounts for environmental friendly wasted deposal management, energy management and used of recycled materials. The panels are also delivered efficiently to reduce carbon footprint.

Panel Customization

FortisLite ALC panel can be manufactured in various sizes based on construction site requirements. It comes in standard sizes or can be cut to specific sizes from seamless installation.

Energy Management

FortisLite ALC panel are light in weight due to its low density based properties. As a result, it allows less consumption during pilling stages, provides better thermal properties which results in energy savings from heating or cooling purposes.