We have been a prominent supplier of AAC/ALC Material in Singapore for 15 years and counting.

We provide the right lightweight solution for your construction needs.

We are the leading

Autoclaved Aerated Concrete (AAC) / Aerated Lightweight Concrete (ALC) Material Supplier

Introduction to

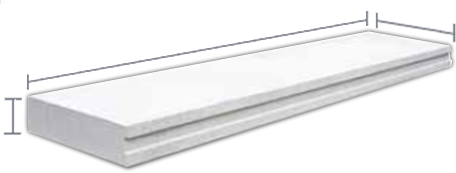

FortisLite Panel

FortisLite Panel is a durable Autoclaved Lightweight concrete panel (ALC).

The FortisLite Autocalved Lightweight Concrete ALC Panel has a wide range of both intrinsic & Extrinsic benefits as a building material compared to traditional masonry products. Properties such as strength, acoustic, density, fire resistances and eco-friendliness are strong points of the FortisLite Panels. The customization and light weight density of the material allows for installation of a wall to be faster, saving on time and overall structural construction cost. Its unique properties of the Autoclaved Aerated Concrete (AAC) material such as thermal insulative strength allows it to help reduce energy wastage from elements such as cooling of a room.

The FortisLite Autocalved Lightweight Concrete ALC Panel has a wide range of both intrinsic & Extrinsic benefits as a building material compared to traditional masonry products. Properties such as strength, acoustic, density, fire resistances and eco-friendliness are strong points of the FortisLite Panels. The customization and light weight density of the material allows for installation of a wall to be faster, saving on time and overall structural construction cost. Its unique properties of the Autoclaved Aerated Concrete (AAC) material such as thermal insulative strength allows it to help reduce energy wastage from elements such as cooling of a room.

Using our FortisLite Autoclaved Lightweight Concrete (ALC) panel system, we strive to deliver exceptional results for our clients in terms of time, labour, structural cost and energy cost savings.

The Autoclaved Aerated Concrete (AAC) Panel Brand that you can Trust

We consistently innovate and analyse market trend regarding Autoclaved Aerated Concrete Panel technology and requirements, Our panel has been tested and achieved various properties such as 4 Hours Fire Rating, 50 STC, Served Duty Rating, 4 Tick Green Certification and more.

Having the technical support of a world-class manufacturer and our years of AAC/ALC material experience, we go above and beyond to serve our clients in their endeavours.

get in touch

Support

We have a team of dedicated technical engineers to provide the right technical solutions and recommendation for you. Our technical engineers will also provide top-notch onsite guidance upon client’s request.

Logistical

We offer storage of materials for customer based on their construction schedule and organize the most efficiently economical transportation to deliver materials in secure lead time for your project.

Accreditation

We constantly maintain our panel test report adhering to regulation and specifications. We also our panel to ensure that it is manufactured to industry strictest ecological requirements standards.

Quality

We manufacture our panel to the most stringent of quality based on ISO 9001:2015 & ISO 14001:2015, This ensures that our panel are of consistent quality, With the capacity of 600,000m2/year to serve our client’s needs.

Step 2:

Treating and Mixing

The raw materials will than be mixed into a slurry using automated process of treating and mixing the raw materials accurately following a formulation for the required strength & density of the panel. The mixture is then poured into moulds, where chemical reactions cause it to rise like a cake in a shape of a log. Steel Reinforced Mesh are inserted in the mixture.

Step 3:

Wire Cutting

Once the cake like mixture has achieved the desired strength, it will then be removed from the mould and wire cut into the desired panels dimension with precision accuracy. The tongue and groove joints are cut before the cake is brought to the next process of autoclaving in order to avoid milling once cake turns to a hardened material.

Step 4:

Autoclaving / Steaming / Curing

Once the desired dimension is cut, the Autocalved Lightweight Concrete (ALC) panel cake is cured by autoclaving inside a steam-tube machine pressured in saturated steam atmosphere at a temperature of approx. 180 – 190°C. This steam curing process allows the ALC panel to achieve a unique crystalline structure that allows the material to inherit excellent properties in comparison to traditional masonry that does not cure using such processes.

FortisLite Autoclaved Aerate Concrete Panel

Durable Autoclaved Aerated Concrete (AAC) / Autoclaved Lightweight Concrete (ALC) Panel

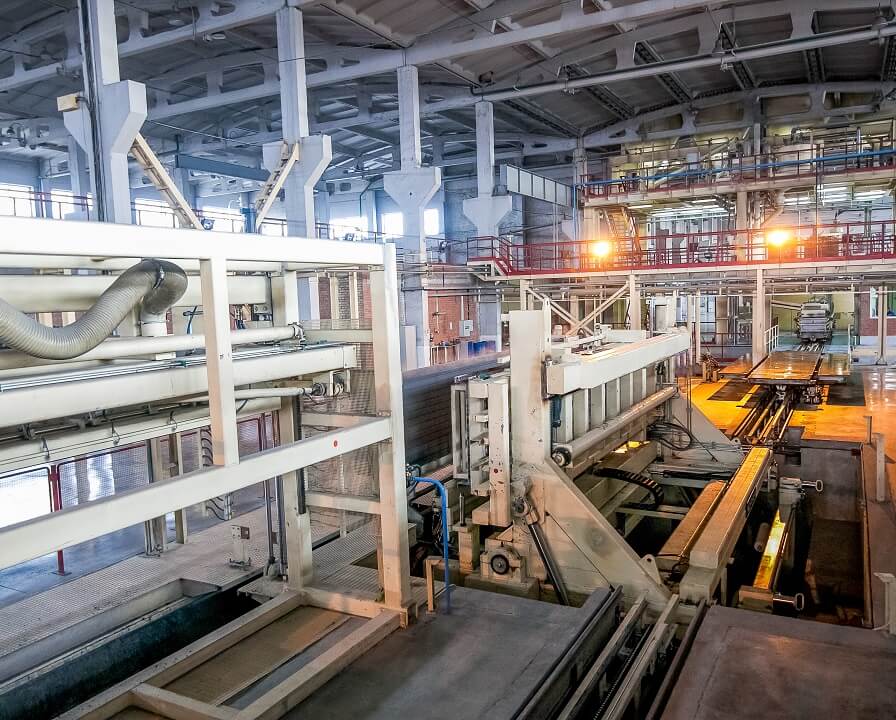

Our Manufacturing plant has the capacity to produce 600,000m2 of AAC/ALC Panel per year to meet local and overseas supply. Our facilities are regularly serviced to ensure functionality and quality of our products. We have a large open space yard to keep our products for any unforeseen needs.

1. Technical Consultancy

We provide technical expertise for technical solutions by recommending the best suitable product according to client’s request and building specification requirements.

2. Design

Advice

We offer related expertise for customer’s building and wall construction design recommendation with Professional Engineer’s endorsement from our typical wall design.

3. Construction Guidance on Site

We offer experienced technical personnel to provide onsite installing guidance upon customer request.

4. Ware housing & Logistical Support

We are able to offer storage of materials for customer based on their construction schedule and organize the most efficiently economical transportation and deliver materials in secure lead time for their project.

5. Specifications Submission Assistances

We constantly upgrade relevant reports and certification to provide product certification, material quality assurance, and sampling testing to give clients the full suite of documentation for their submission.

6. Aftersales Services

We value your trust in us and hope to maintain that trust by providing after sales support for construction site visitation regarding any technical support required during construction.

Autoclaved Aerated Concrete (AAC) / Autoclaved Lightweight Concrete (ALC) Panel Vertical Installation

Vertical Installation are recommended for internal installation. Vertical installation allows for coverage over a wider column to column wall span without stiffener. External installation are also applicable.

Autoclaved Aerated Concrete (AAC) / Autoclaved Lightweight Concrete (ALC) Panel Horizontal Installation

Horizontal Installation are recommended for external installation. Horizontal Installation allows for coverage over a higher floor to ceiling wall span without lintel. Internal installation are also applicable.